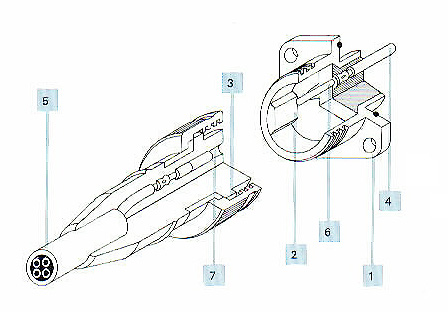

SEAMAX Connector

Design Features

Underwater Systems has incorporated numerous unique design features into the SEAMAX series of underwater connectors. SEAMAX connectors provide reliable electrical and pressure performance similar to that of the best glass-sealed designs at a fraction of the cost.

All SEAMAX connectors use rugged metal shells, precisely machined from single pieces of high grade stainless steel or aluminum. Using one high pressure molding operation, Underwater Systems molds pressure seals and contact pins into the connector with high density neoprene rubber. Proprietary thermosetting compounds are then used to perma nently encapsulate terminated wiring and to reinforce the pressure sealing system.

SEAMAX connectors are constructed in four primary designs.

They are the following:

TYPE ER These economical connectors are identified by their prominent rubber keys and keyways. These connectors have excellent contact density. Connectors may be mated while they are wet, although they should not be mated while submerged.

TYPE EB These connectors are identi- fied by the single machined keys and keyways. Type ER connectors offer good contact density, greater resistance to rough handling, and improved pressure performance. Connectors may be mated while faces are wet, but they should not be mated while submerged.

TYPES ERPB & EBPB These connectors are engineered for construction into oil-filled, pressure balanced cable assemblies. Connectors have metal backshells which include an oil-fill port. These connectors can be conveniently field assembled with cable and oil-fill tubing.

TYPES EC These connectors are designed to meet the need for high density contact arrangements in underwater connectors. They are ideal for medium duty applications, and they are suitable for use in depths of 2,500 feet

- Connector shells are machined from single pieces of stainless steel or aluminum (anodized).

- Keys are integral with connector shells. Type ER connectors use molded rubber keys. Types EB and EC use machined keys.

- Contacts of ER and EB connectors are molded into insulators to ensure water-blocked construction.

- Panel-mounted connectors are supplied with Teflon ฎ insulated pigtails.

- Connector backshells are vulcanized to high grade underwater cable on in-line connectors.

- Contacts are high conductivity copper alloy.

- Individual contact seals on ER and EB connec- tors provide electrical integrity even when insert faces are wet.

Design Data

The SEAMAX series of connectors are engineered to the most exacting quality standards

to ensure an extended service life in undersea environmental conditions. Connectors are

designed to exceed all standards of MIL-C-

24231. Connectors also meet many requirements of MIL-C-24217 Below is a brief

summary of mechanical, environmental, and

electrical design data.

STANDARD CONSTRUCTION MATERIALS

SHELLS Passivated stainless steel, or

anodized aluminum

COUPLING NUTS Aluminum bronze or

anodized aluminum

INSULATOR Neoprene rubber

CONTACTS High conductivity copper alloy

ENVIRONMENTAL DESIGN

HYDROSTATIC PRESSURE

Connectors have

been designed to withstand

the following

pressures:

Connector Types ER and EB

Mated 10,000 psi

Unmated 10,000 psi

Type EC

Mated 1,200 psi

Unmated Not recommended

Oil-Filled Connectors, Types ERPB & EBPB

Only panel mounted connectors are

designed to withstand pressure differentials.

Mated1O,000 psi

Unmated1O,000 psi

OPERATING TEMPERATURES

-50oC to +90oC

THERMAL SHOCK

-40oC to +75oC

CORROSION RESISTANCE Exceeds

MIL-STD 202, Method 101, Condition D

VIBRATION Meets Type I requirements of

MIL-STD-167-1

NUMBER OF CONTACTS 1 to 41

INSULATION RESISTANCE Better than

2,000 Megohms

DIELECTRIC WITHSTANDING VOLTAGE:

Type ER 2300 volts rms

Type EB 2300 volts rms

Type EC 1500 volts rms

VOLTAGE RATING 600 volts, unless

otherwise indicated